Milk & Food Processing

Processing is a term used to describe steps that are taken after the product leaves the farm, and before it is ready for retail sale. Many foods undergo various food processing procedures. Examples include curing Pork to make ham and bacon, turning apples into applesauce or cider, and squeezing oranges for orange juice. Food processing is a benefit to consumers. Food processing provides a greater variety of food to eat as well as food that is safer for human consumption. Without food processing our diets would consist of whole, raw foods exactly as they were produced on the farm and only in the season or shelf life of the food item. In addition, without food processing, consumers are at a greater risk of food-born illnesses.

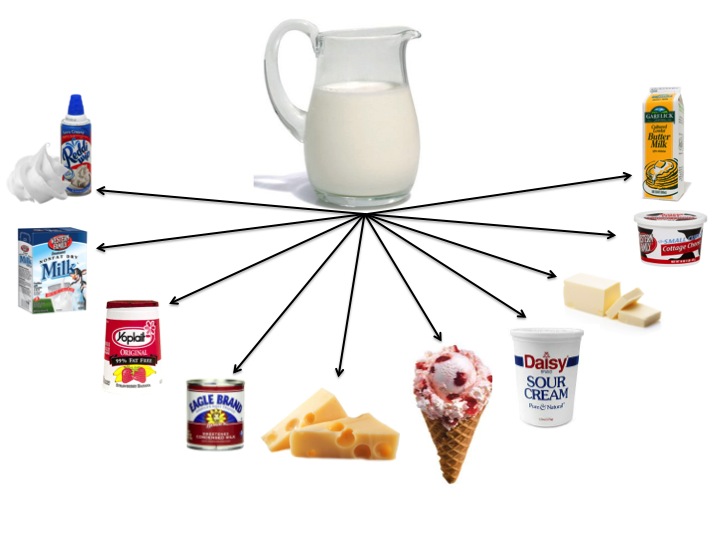

Milk undergoes processing after it leaves the dairy farm. The fluid milk we drink and the milk that is used to make other dairy products such as ice cream, yogurt, and cheese is typically produced by cows on a dairy farm. In the United States, goats only provide a very small portion of milk for specialty markets. Milk leaves the dairy farm and must be processed prior to being sold to consumers. Fluid milk in the United States is pasteurized, homogenized, fortified, and standardized before it is sold to consumers.

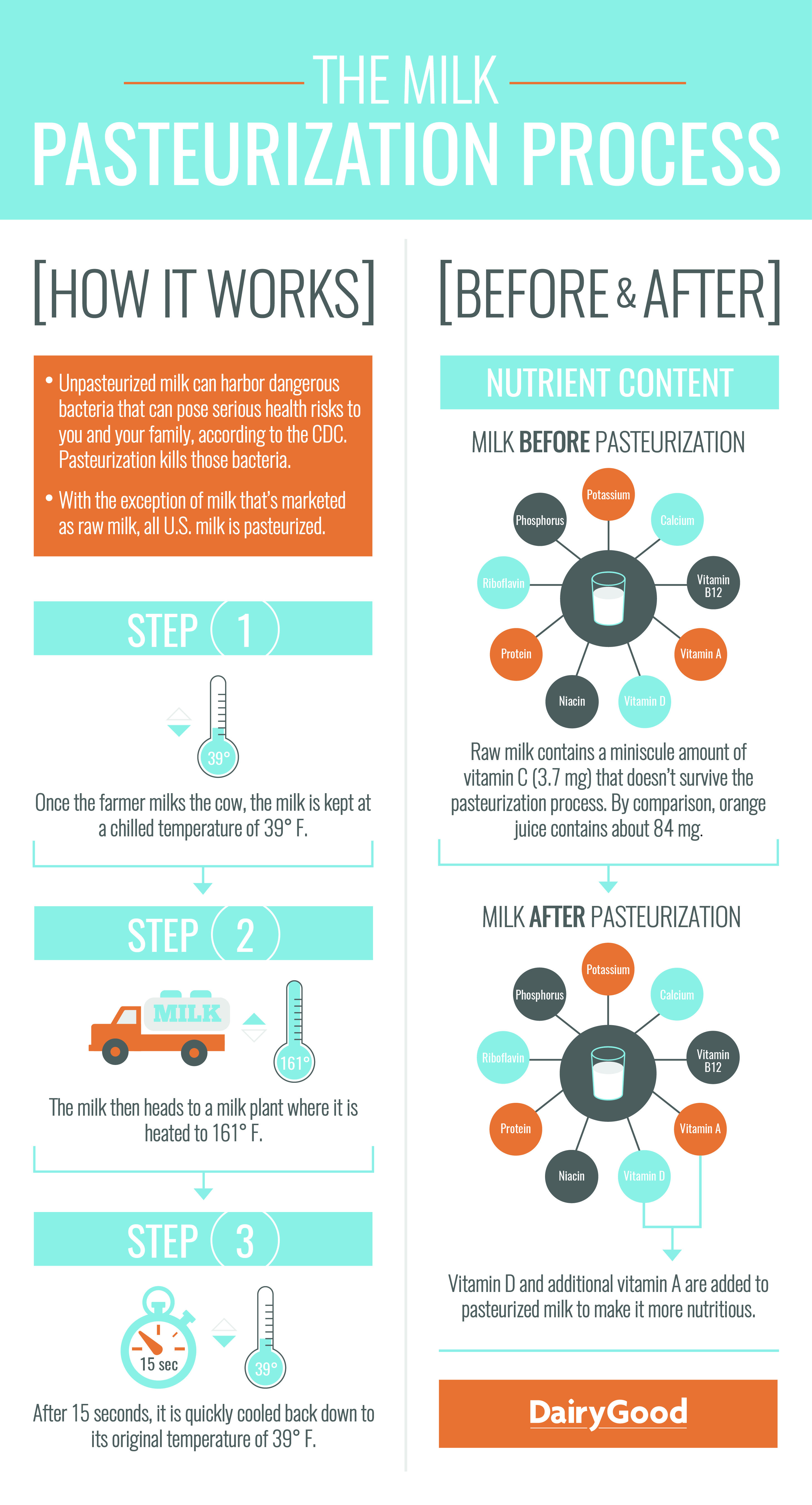

- Pasteurization is a process originally created by Louis Pasteur in the mid 1800's. During pasteurization, milk (or another liquid) is heated to destroy microorganisms. As pasteurization practices became more common and eventually mandatory, milkborne diseases such as typhoid fever, scarlet fever, diphtheria, and diarrheal diseases were virtually eliminated. These diseases were especially devastating to young children and infants. Today, each state administers its own laws as to whether milk can be sold without pasteurization.

- Homogenization breaks up or shears the fat molecules (cream) in milk so that they are the same size and density of the rest of the milk. This results in a uniform texture and stops the cream from separating and rising to the top of the milk.

- Vitamin Fortification. Fluid milk in the United States is often fortified with Vitamin A and D. Vitamins A and D are found naturally in milk, however, they are fat-soluble vitamins. Milk with reduced fat levels (2%, 1% or skim) does not contain adequate levels of vitamin A without fortification. Vitamin D is critical to calcium absorption. Adequate calcium in our diet for healthy bones and teeth is only valuable when accompanied with vitamin D.

- Standardization. An important component of milk is fat. The percentage of fat found in milk depends on the species and breed of the animal that produced it. Other factors such as the animal's nutrition and the stage of lactation affect fat content. Most cattle produce milk with 3-5% milk fat. Consumers desire milk that is consistent in flavor and texture each time they purchase it. Consumers also desire lower fat milk products. Standardization is the process of removing fat from milk and adding it back to achieve the desired fat content. Whole milk (3.25%), 2%, 1% and skim (<.1%) milk are the result.

Physical & Chemical Changes

Once milk is pasteurized and homogenized it can be used to make many different food products. Each process requires milk to undergo a physical or a chemical change.

Physical changes can occur without altering the chemical composition of a substance. Physical changes can include changing the color, shape, state of matter, or volume of a substance. With many physical changes, the process can be reversed and return the product to it's original state. The following dairy products undergo a physical change:

- Butter: Butter is made using the cream (fat) found in milk. Through a process called churning, the fat globules in the cream separate from the buttermilk (remaining liquid) and make butter.

- Whip Cream: Whipping cream is made using the cream (fat) found in milk. When the cream is vigorously mixed or shaken the fat molecules begin clumping together thickening the once liquid cream into the solid state of whipping cream.

- Powdered Milk: Powdered milk is made by first concentrating milk until it is 50% solids. The concentrated milk is then heated. The water in the milk evaporates leaving a powder which can be stored and reconstituted later.

- Sweetened Condensed Milk: To make sweetened condense milk, milk is heated to evaporate water from the milk. This makes the milk thicker and more dense. Sugar is then added to sweeten the condensed milk. The sugar gives it the syrup-like consistency.

- Ice Cream: Ice cream is made first by mixing milk, cream, and sugar together. The mixture is then frozen into ice cream.

Chemical changes occur when bonds between atoms are made or broken. A new chemical substance is formed as a result and the process is permanent. The following dairy products undergo a chemical change:

- Cheese: Cheese is made when an enzyme called rennet is added to milk. The rennet causes a chemical reaction where the milk solids curdle, separating themselves from the whey, or liquid portion of the milk.

- Yogurt: Yogurt is made by adding a specific bacteria to heated milk. The milk is then incubated at a specific temperature for a period of time. The bacteria converts the lactose, or milk sugar, to lactic acid. This process thickens the milk and gives it the tangy taste.

- Sour Cream: Sour cream is made by adding a specific kind of lactic acid bacteria to cream. The addition of the lactic acid sours and thickens the cream.

- Cottage Cheese: Cottage cheese is made by adding an enzyme to milk causing it to curdle. Unlike hard cheeses, the cheese curds remain loose and are mixed with the whey (liquid portion) to create cottage cheese.

- Buttermilk: Buttermilk is made by adding a lactic acid bacteria to milk, giving it its characteristically sour taste.

In summary, physical changes occur in dairy products when water is simply evaporated from milk (powdered milk and sweetened condensed milk), when churning or whipping causes the fat molecules to stick together (butter and whip cream), or when a sugar is added (ice cream and sweetened condensed milk). Chemical changes occur when bacteria, acids, or enzymes are added to milk changing its taste, texture, or consistency.