Bread has been an important part of the human diet since early times. Loaves baked over 5,000 years ago have been found in ancient Egyptian tombs. Wheat has been discovered in pits where human settlements existed 8,000 years ago. In the Stone Age, solid cakes were made from crushed wheat. Bread provided ancient civilizations with a reliable food source.

The wheat plant has four basic parts—roots, stem, leaves, and head. The roots anchor the plant in the soil, absorbing water and nutrients and transporting them to the stem. The stem supports the head and helps transport nutrients and water throughout the plant. The leaves are responsible for photosynthesis. The head of the wheat plant contains the wheat seeds, also referred to as kernels or berries.

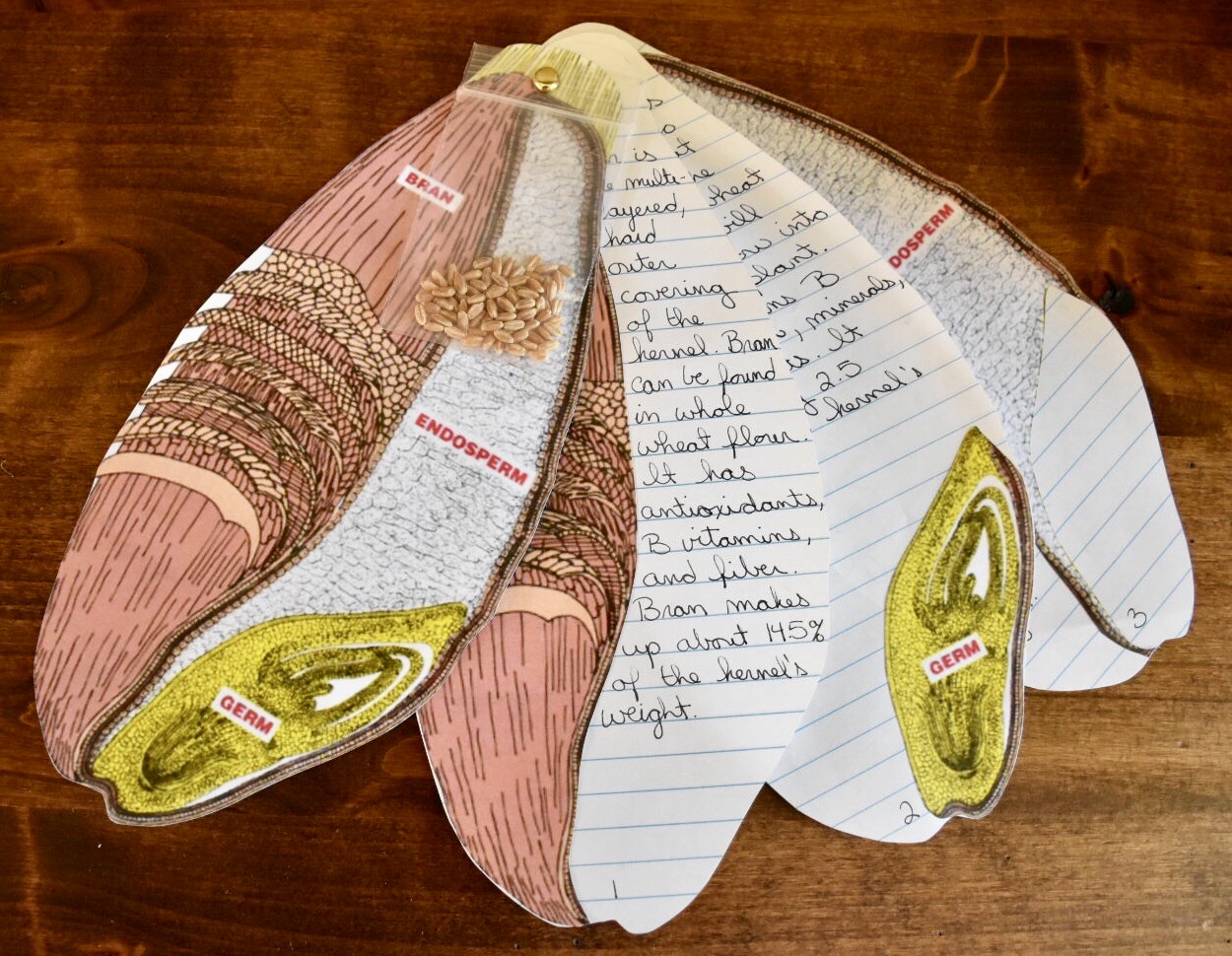

Wheat flour is made from the kernels of the wheat plant. The kernel is the seed from which the wheat plant grows. A wheat kernel contains three distinct parts—the bran, germ, and endosperm. The bran is the multi-layered, hard outer covering of the kernel. Bran consists of important antioxidants, B vitamins, and fiber. The germ is the embryo or sprouting section of the kernel. It is the part of the wheat kernel that will sprout and grow into a new wheat plant. During the milling process, the germ is often separated from the flour because its fat content limits the flour's shelf-life. The germ contains B vitamins, protein, minerals, and healthy fats. The endosperm is the germ's food supply. In its natural state, the endosperm provides essential energy to the young wheat plant, allowing the plant to send roots down into the soil to absorb water and nutrients and shoot sprouts up for sunlight.

In Neolithic times, saddle stones (cradle-shaped pieces of hard stone) and hand stones (cylindrical-shaped stones) were used to crush grain into coarse flour. In the Stone Age, hand-powered rotary querns consisting of a rotating circular stone on top and a stationary stone on the bottom to grind grain. In the 18th century, automated stone wheels, powered by wind or water, rose in popularity as a method of flour production. The invention of the roller mill in the middle of the 19th century increased the productivity of flour mills. Commercial flour mills today still use the roller mill, however they are utilizing the advances in modern technology to improve the efficiency, reliability, and safety of flour production.

When wheat arrives at the mill, it is weighed, tested, cleaned, and conditioned. To condition the wheat kernels, water is added to the grain in order to toughen the outer part of the wheat and soften the inner part. The wheat then rests for about twelve hours. Steel rollers break open the grain to release and separate the endosperm from the bran and the germ.The starchy endosperm is ground and sifted several times to make white, all-purpose flour. When making whole wheat flour, the bran and germ is put back into the white flour at the end of the milling process. The flour is then packed into bags to be transported to stores, bakeries, and food processing plants.

types of bread from around the world that are featured in the book.

types of bread from around the world that are featured in the book.