The United States ranks second in the world for cheese production and produced about 6 million metric tons of cheese in 2020.9 In 2021 it was estimated that over 55,000 people were employed in the cheese production industry in the United States. Cheesemaking is a science, an art, and a craft. Science is the tool to transform milk into cheese. Art accounts for the creative skills used in the development of new cheese flavors and varieties. Crafts represent activities requiring skill. Cheesemaking requires many skills.

Origin of cheese

Cheese is one of many products made from milk. The exact date of origin for cheese is unknown, but it has been found in Egyptian tombs and murals from 4,000 years ago. It is thought that cheese was discovered by accident when it was common to store milk in a container made from an animal stomach. The enzyme, rennet is found in ruminant stomachs. When added to milk it causes milk to coagulate and separate curds (solid proteins) from whey (liquid). This means when someone would store milk in a ruminant stomach (a common practice before glass and plastic), their milk would turn to fresh cheese.

Today, the art of making cheese has become much more technical.4 Now there are hundreds of cheese varieties which can be grouped into eight categories including blue, hard, pasta filata, processed, semi-hard, semi-soft, soft and fresh, and soft-ripened.5 Currently more than one-third of all milk produced each year in the United States is made into cheese.6

Cheesemaking Process

The cheesemaking process uses science and chemistry to remove whey and liquid from milk to form a curd (cheese).7 Along with a vast array of cheese types, there is also a variety of cheese-making processes. Each process shares the same basic components:

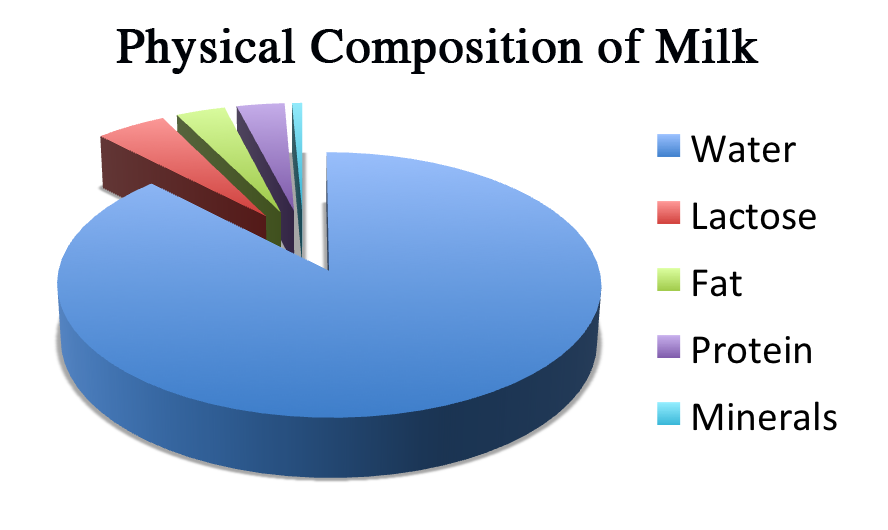

- Milk: All cheese is made from milk. In the United States, milk from cows is most common. However, many specialty cheeses are made from the milk of sheep, goats, and other mammals. Milk is composed of varying amounts of carbohydrates (lactose), fat, protein (casein and whey), vitamins, and minerals.

- Acid: Soft cheeses are made by adding a type of acid to milk to make it coagulate. Citric acid and vinegar are two examples of acids used in the cheesemaking process.

- Bacterial Cultures: Chemical changes in milk can be triggered using bacterial cultures. The use of beneficial bacteria creates chemical responses in the cheese to enhance specific flavors.

- Enzymes: The most common enzyme used to make cheese is Rennet. Rennet causes the milk to coagulate and is used to make hard cheeses.8 It helps the milk mixture separate the forming curds from the whey. Rennet splits off the hydrophilic portion of the casein micelles so it will no longer stay suspended in the aqueous solution of milk. Instead, the casein aggregates together to form the curds, while the whey (or liquid portion) separates.7

- Time: Some cheeses can be made in a short amount of time and others require aging to develop the proper flavor, texture, and moisture levels.

- Heat: Precise temperatures allow the enzymes and bacterial cultures to work properly in the cheesemaking process by allowing the beneficial bacteria to do its work.8

- Salt: Salting helps draw out additional moisture in the cheesemaking process. It also plays a huge role in the flavor of cheese.

Careers in the Cheese Industry

There are a variety of career opportunities that help keep cheese coming to our local grocery store. Artisan cheesemakers often work in shops to perform each step along the entire milk-to-cheese process. Some specialty shops may even raise their own dairy animals (cattle, sheep, or goats) for the milk that makes their cheese. There are also careers working in large cheese processing facilities used to stock grocery stores and food services across the country. These careers require a variety of training and education in the subjects of microbiology, chemistry, food science, or process engineering. Specific tasks include research and development, quality control, technical services, customer service, and sales.